Sanitary Crane for the Electronics Semiconductor Process

In the continuously growing and rapidly evolving electronics industry, a vast number of parts are moved throughout the supply chain on a daily basis.

The production process of electronic components and semiconductors demands precision and cleanliness. Clean room cranes are an essential tool in this industry, as they ensure a dust-free environment throughout the process, guaranteeing the production of high-quality electronic products.

Sanitary cranes serve multiple purposes in the electronics industry:

1. Raw material handling and storage

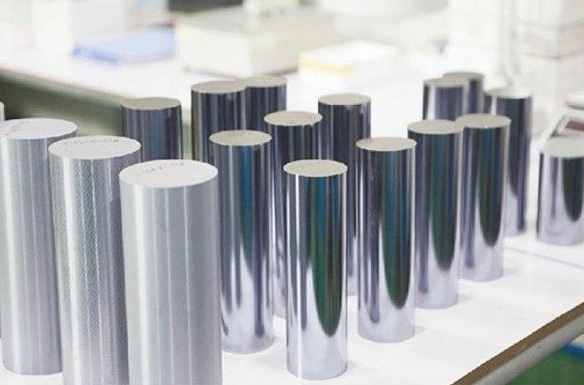

In the initial stages of the production, clean room cranes transport sensitive electronic materials such as silicon wafers and thin film materials, ensuring that they are free from dust and particle contamination during handling. The precise positioning system helps orderly storage of materials, reducing the risk of damage.

2. Process transfer and processing

Sanitary lifting cranes play a crucial role in the wafer manufacturing process by accurately transferring wafers from one processing station to another, such as cleaning, etching, deposition, etc. This process is carried out in a dust-free environment, avoiding particle contamination of the wafer surface and improving the performance and reliability of semiconductor devices.

3. Equipment maintenance and upgrades

Sanitary lifting cranes can safely lift and move large equipment, such as photolithography and etching machines, during maintenance and upgrade of electronic production equipment. They ensure that no contaminants are introduced during the maintenance process, reducing downtime, and improving production efficiency.

4. Component assembly and testing

Sanitary lifting cranes handle and position precision electronic components such as circuit boards and microelectronic modules during the assembly and testing stages of electronic components. Their precise operation ensures that components are precisely aligned during assembly, reducing damage caused by improper operation. They also ensure a clean test environment during the testing phase, improving the accuracy of test results.

5. Packaging and shipping

Clean room cranes are used to pack electronic components or equipment in a dust-free manner before shipment, ensuring that the entire process is kept clean and that there is no possible contamination introduced during the handling process.

In summary, sanitary lifting cranes are an essential tool in the electronics industry, participating in and optimizing the production process from raw material processing to finished product delivery. Their precise handling and dust-free environment provide a solid foundation for the high-quality production of electronic products and are an important tool for the electronics industry to achieve efficient, precise, and clean production.