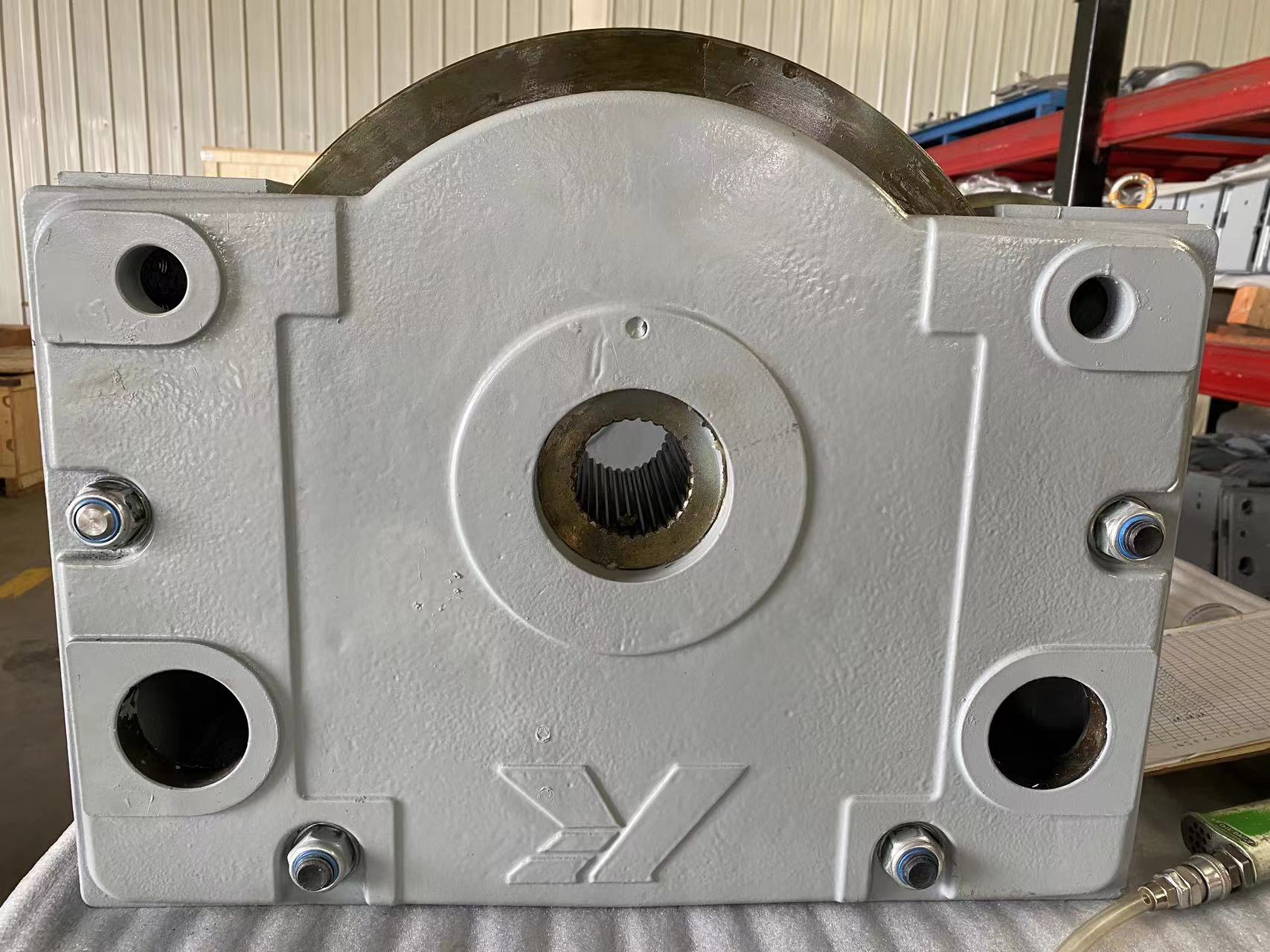

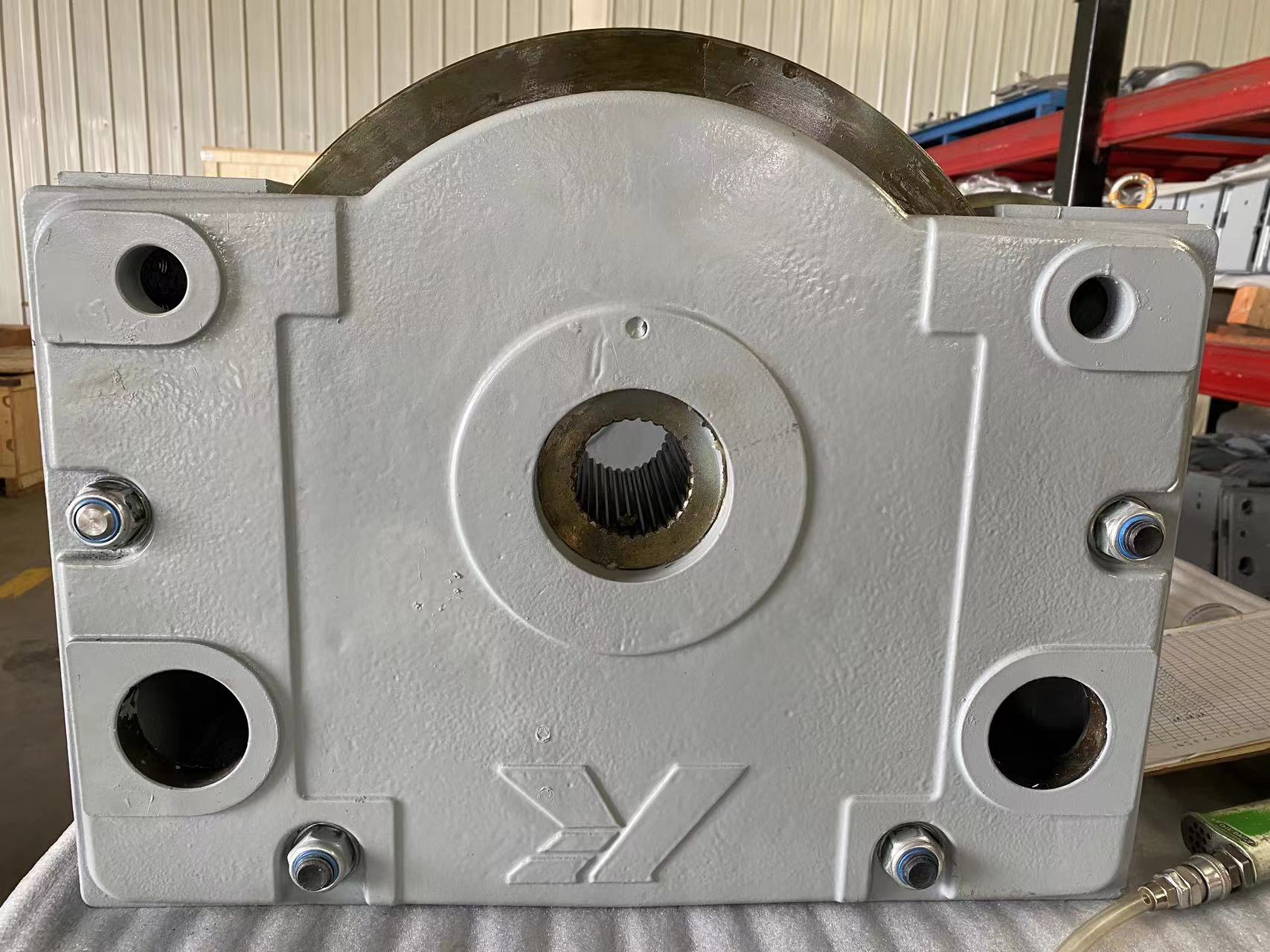

The drive wheel block is a key component used to provide the walking and moving functions of construction machinery and heavy equipment. The DRSA 160 drive wheel is a specific type of traveling wheel box. It transmits power to the drive wheels through the travel wheels and transmission devices, promotes the walking motion of the equipment, and carries and supports the weight of the equipment.

Manufacturing Process

Design and engineering analysis: Based on the use requirements and application scenarios of the driving wheel, design and engineering analysis are conducted to determine the size, structure, load-bearing capacity and other parameters of the driving wheel.

Material selection: Select appropriate materials for manufacturing based on design requirements and application scenarios. Depending on the material properties, processes such as material processing and heat treatment may be required.

Processing and manufacturing: Processing and manufacturing of driving wheels according to design drawings and process requirements. This includes material cutting, turning, milling, drilling, welding and other process steps. Dimensional accuracy and surface quality need to be ensured during the manufacturing process.

Heat treatment: For some metal materials, heat treatment processes, such as quenching, tempering, etc., may be required to improve the strength and hardness of the material.

Surface treatment: The surface of the driving wheel usually requires surface treatment to improve its wear resistance, corrosion resistance and appearance quality. Common surface treatment methods include chrome plating, spraying, anodizing, etc.

Assembly and inspection: Assemble the manufactured driving wheel and conduct quality inspection. Inspection includes dimensional measurement, material inspection, appearance inspection, etc. to ensure that the driving wheel meets the design requirements and quality standards.

Product Features of DRSA 160 Drive Wheel

High-wear-resistance material for heavy-duty operation

High machining precision to minimize track wear

Modular drive design

Compatible with multiple track specifications

Customization available upon request

If you are looking for wheel block system solution, please click to contact us for a free customized solution and product quotation.

Get In Touch

Have inquiry or question for our products, please kindly leave us your message and we will get back to you within 24 hrs. You can also contact us via email.