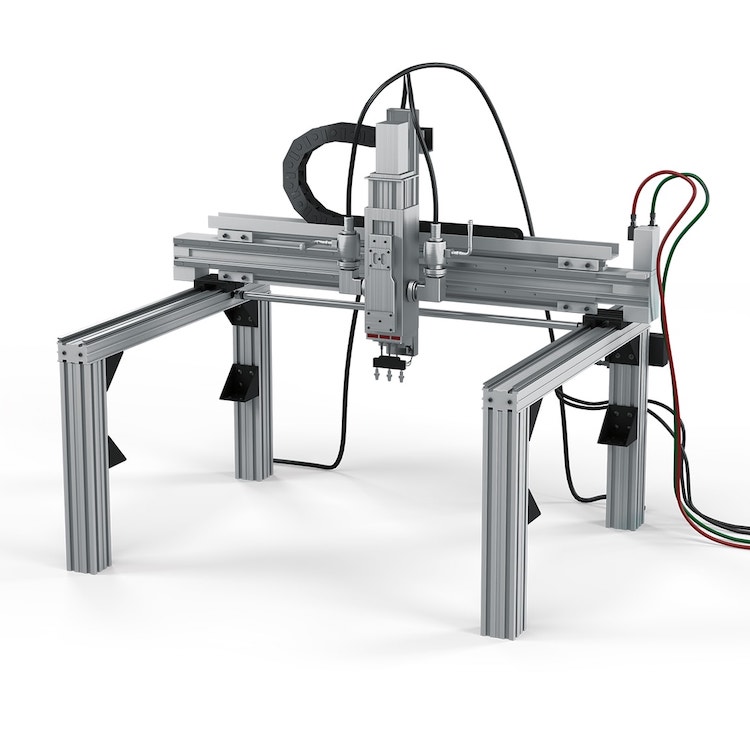

Automatic Loading and Unloading Intelligent Truss

Intelligent loading and unloading truss is also called truss robot, also called Cartesian robot and gantry robot. It is an automation equipment that can realize automatic control, is reprogrammable based on the XYZ Cartesian coordinate system in space, has multiple degrees of freedom, and is suitable for different tasks. It can carry objects, assemble, cut, operate tools to complete various tasks. The truss manipulator has simple and reliable structure, convenient maintenance and operation, and low investment cost; it has high precision and adopts ground precision gear and rack drive, which increases the mechanical working load and improves the operation stability. It is suitable for short processing cycles and large production batches.

The intelligent loading and unloading truss structure is a truss structure that uses intelligent technology to realize automatic loading and unloading operations. The structure includes a truss robot arm, which can automatically complete the loading and unloading operations according to preset programs and instructions. Truss manipulators usually consist of multiple joints, each of which can be rotated or stretched. This structure can provide flexibility and precision, can adapt to objects of different shapes and sizes, and can operate in tight spaces.

Features of loading and unloading intelligent truss:

● It can sense the position and status of materials through sensors, and perform automatic loading and unloading operations according to preset procedures without manual intervention.

● It can quickly and accurately carry out loading and unloading operations, improve production efficiency and reduce labor costs.

● It can be automatically adjusted and adapted according to different workpiece sizes and shapes, and is suitable for various loading and unloading tasks.

● Equipped with multiple safety devices and protection measures, such as anti-collision devices, emergency stop buttons, etc., to ensure the safety of the operation process.

● It can record and analyze the data in the loading and unloading process, provide statistics and analysis of production data, and help optimize production management and adjust process flow.

● Simple operation, friendly interface, easy to use and maintain.

Truss robots provide automation solutions for parts processing of CNC lathes, vertical machining centers, horizontal machining centers, CNC vertical lathes, CNC grinding machines, CNC gear grinding machines, CNC welding, CNC cutting and other equipment.

Get In Touch

Have inquiry or question for our products, please kindly leave us your message and we will get back to you within 24 hrs. You can also contact us via email.