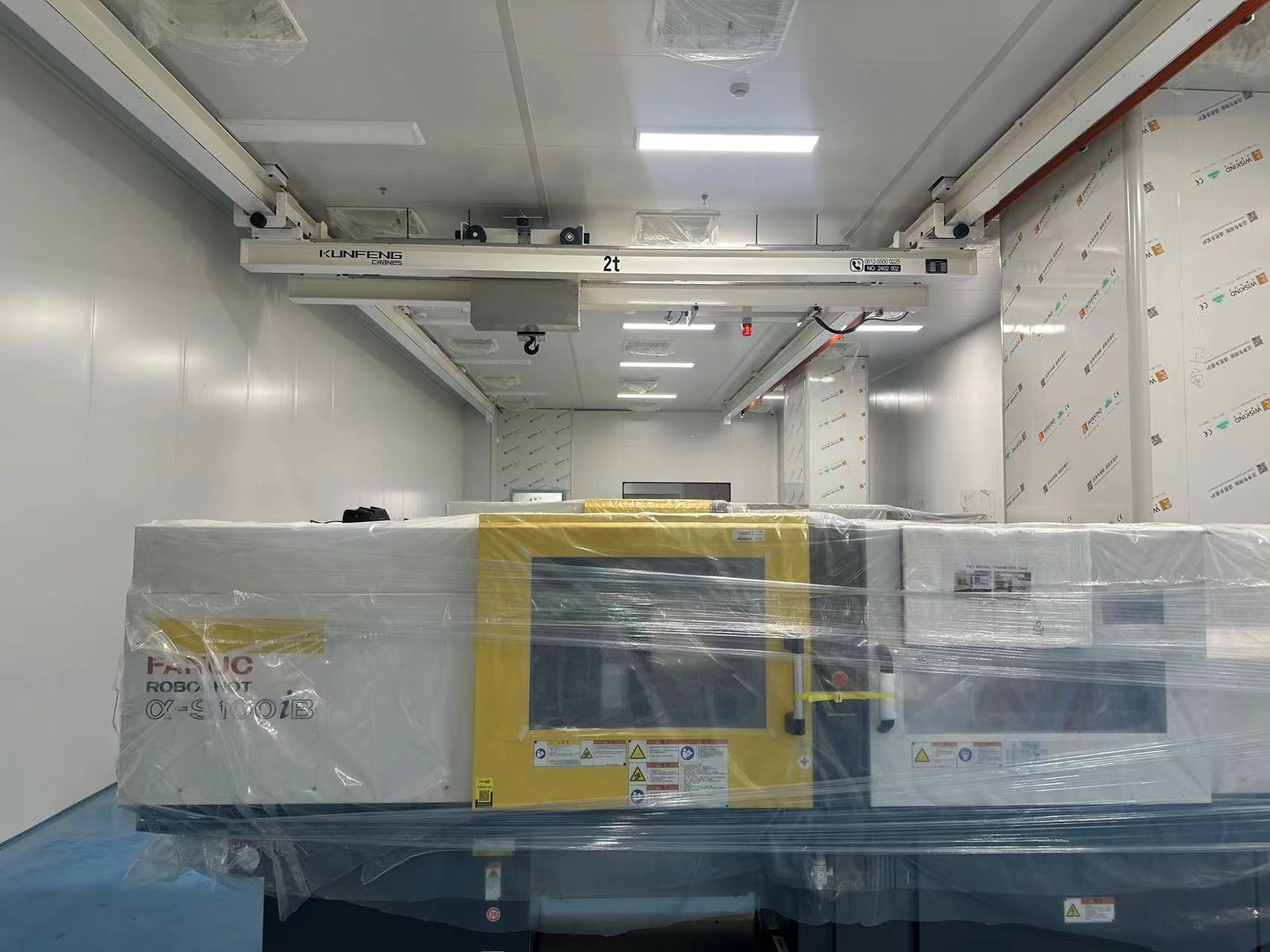

With the rapid development of high-precision industries such as electronics, semiconductors, pharmaceuticals, biotechnology, and new energy, cleanroom crane systems, as lifting equipment designed for dust-free and sterile environments, have the characteristics of low particle release, corrosion resistance, and easy cleaning. The crane is usually composed of clean rails, electric hoists (with dustproof design), stainless steel or anodized structural parts, oil-free lubrication parts, and a dedicated control system, which can achieve precise, safe, and stable lifting operations.

Main features of cleanroom cranes

All parts are made of stainless steel or special coatings to reduce particle shedding and dust accumulation, meeting cleanroom standards such as ISO 14644 and GMP.

Equipped with a frequency conversion control system to achieve precise lifting and smooth operation, effectively reduce hook swing, and improve work efficiency and safety.

A variety of configurations are available, including bridge, suspension, jib, gantry and other structures to meet the use requirements of different clean areas.

Smooth surface, simple structure, no dead angle design, easy to clean and maintain regularly, and reduce the risk of cross contamination.

Optional remote control, electronic limit, and automation interface are available for easy integration into the overall intelligent system of the cleanroom.

Typical application scenarios

Semiconductor wafer handling

Material transfer in clean areas of pharmaceutical production

Precision instrument assembly area

Food and biological laboratories

Dust-free manufacturing lines in the optical and aerospace industries

Technical parameters (partial reference)

Lifting capacity: 100kg - 10,000kg

Lifting height: 2m - 12m (customizable)

Operation mode: electric / manual

Control system: wired / wireless / PLC integration

Lifting device: electric hoist / manual hoist

We are committed to providing customers with lifting system solutions that meet industry standards and support personalized customization, helping companies achieve high cleanliness, high efficiency and high safety production goals. If you need more technical information or customized services, please contact our technical team to obtain exclusive solutions.

Get In Touch

Have inquiry or question for our products, please kindly leave us your message and we will get back to you within 24 hrs. You can also contact us via email.