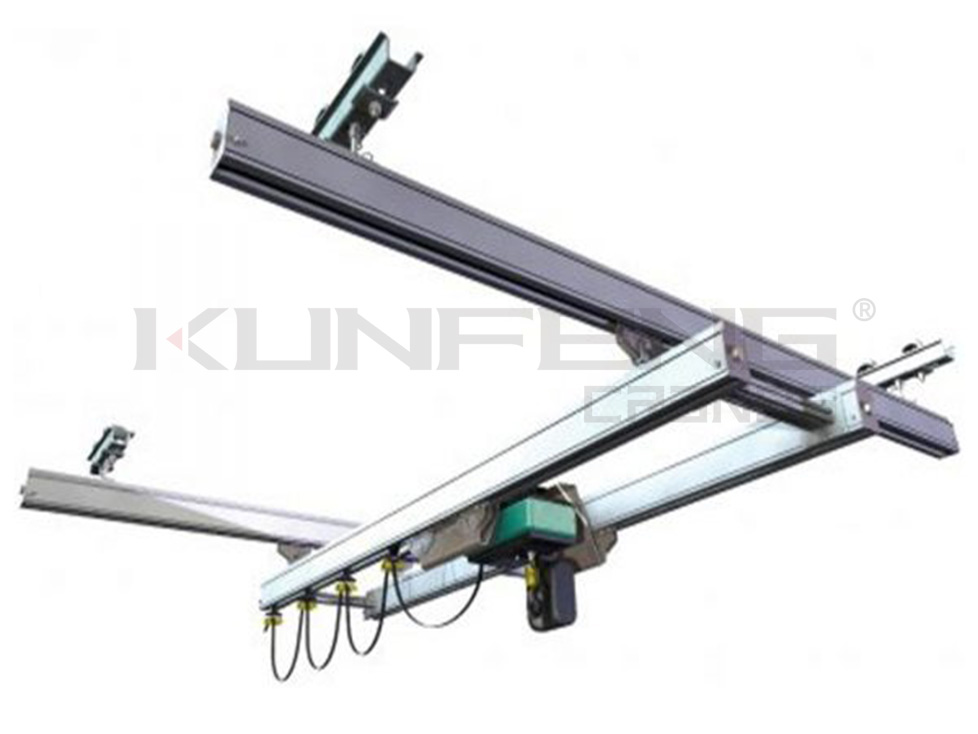

KBK Crane Application in Clean room

In some technical fields, such as electronics, precision machinery and pharmaceutical industries, there are special clean requirements for the air in the workshop. Its purpose is to eliminate the harmful effects of air pollutants on the objects to be handled or on people at the work station.

KBK Crane Application in Clean room:

According to the clean room, the clean room is classified according to the number of particles contained in the unit volume of the air. The class of clean air is determined by measuring the concentration of particles. If the measured particle concentration value is less than the specified concentration limit for particles of the specified size, it is considered to be in compliance. The particles can be in solid or liquid form. Certain particularly sensitive processes, such as evaporation from greases used in the production of individual components, can also have a detrimental effect. Lifting gear and trolleys used in cleanrooms must be specially designed and manufactured so that they do not generate particles during operation, especially from friction, corrosion or vibration. Demag's classic DC electric chain hoist and light-duty crane composed of aluminum alloy rails can be used in clean rooms up to 10,000 class. The aluminum alloy track is used in the clean room. The surface of the aluminum alloy track is anodized and durable, which can prevent the surrounding environment from corroding and impacting, and effectively prevent the crane from producing particles due to corrosion. The aluminum alloy track has a low self-weight. The combination of the lightweight aluminum rail profile and the smooth running trolley makes the crane run extremely smoothly. It only needs a little force to move and brake the load quickly, avoiding the crane generating particles due to vibration. KBK aluminum alloy rail crane adopts high-quality nylon walking wheels, which can be suitable for clean room without special measures. Closed crane end beams meet the requirements of class 10,000 clean rooms: KBK cranes are usually used in machine tool parts and other environments, so when choosing an electric hoist, special attention must be paid to its speed control requirements, so that according to The specific descending speed when the user is hoisting is carried out slowly, so as not to collide with the hoisted object. When operating the equipment, the user must have professional work experience and the ability to recognize the dangers of illegal operations. Only operators who meet these standards can ensure the safety and efficiency of use. Before operating the equipment, they must also Carry out professional and effective inspection of the equipment, if any wear or failure is found, it needs to be repaired in time. Since the crane is suspended on the bottom chord of the track I-beam, the manual monorail trolley is suspended on the main beam of the large frame, and the travel between the taxi and the manual monorail trolley and the goods in it are driven by the manual zipper; this This kind of equipment is usually used in warehouses and workshops with normal room temperature, and is suspended and installed on the I-beam track of fixed span for loading, unloading and transporting heavy objects or overhauling equipment.

KBK crane is a kind of equipment with light working intensity. It is composed of electric hoist and driving device. At the same time, KBK cranes use special engineering plastic wheels with rolling bearings, which can travel faster and have less friction. In addition, the structure of KBK crane is simple, and the size of engineering plastic wheels is small, so it is particularly beneficial to improve the stroke of the hook. However, due to the steel structure and the large volume, transportation is not a small difficulty. Once a transportation problem occurs, it will not only deform the KBK crane, but even endanger the safety of the transporters.

This is the relevant introduction of KBK rail crane. In the process of using this equipment, if you want to give full play to its professional advantages, the method of safe operation of the machine not only needs to ensure the quality of the equipment itself, but also pay attention to the effect of installation. At the same time, the operation method and operation Security must also be guaranteed, and only in this way can users achieve their intended purpose of use.

Lifting machinery usually has a bulky structure and a relatively complex mechanism. The kbk track is composed of suspension devices, rails, turnouts, walking trolleys, electric hoists, mobile power supply devices (slide lines) and control devices. It only needs to be simply hung on the roof or beam frame of the workshop to realize the material in the air. Direct conveying, so it is widely used in material conveying links or systems in all walks of life. The cantilever crane is an industrial component and is a light-duty crane. It consists of a column, a slewing arm slewing drive device and an electric hoist. It has light weight, large span, large lifting capacity, economical and durable. Generally, various actions such as lifting, running, luffing, and turning can be performed. In addition, there are many parts of the hoisting mechanism, such as hooks, wire ropes (composed of steel wires, rope cores and grease), etc., and they are often in direct contact with operators. It is relatively difficult for crane drivers to accurately operate.

KBK Crane Application in Clean room